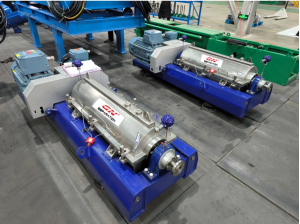

GN Separation, a global leader in separation solutions, recently completed the delivery of two GNLW224 Decanter Centrifuges to an esteemed client in Australia. This strategic move underscores GN’s commitment to excellence and signifies a targeted expansion into the Australian market.

**Tailored Solutions for Enhanced Efficiency**

Customized to maximize efficiency, the GNLW224 Decanter Centrifuges feature ABB brand motors, ensuring robust performance and reliability. Equipped with bearing temperature and vibration sensors meeting IEC Ex explosion-proof standards, these centrifuges prioritize safety in hazardous environments. The versatility of the GNLW224FT model optimizes processing operations, minimizes waste, and improves material recovery, aligning with GN Separation’s dedication to providing premier separation solutions.

**Key Features and Applications of 2-Phase Decanter Centrifuges**

As vital industrial equipment, 2-phase decanter centrifuges play a crucial role in separating immiscible phases, particularly liquids and solids. Offering continuous operation, high separation efficiency, and large processing capacity, these decanters find versatile applications across industries including oil and gas, chemical, pharmaceutical, and wastewater treatment. With adjustable parameters, robust construction, and advanced automation, GN 2-phase decanter centrifuges ensure precise separation tailored to specific industrial requirements.

In conclusion, GN Separation’s successful delivery of GNLW224 Decanter Centrifuges to its Australian client not only strengthens its presence in the region but also exemplifies its commitment to providing cutting-edge technology tailored to meet the evolving needs of global industries.