In a recent project in domestic China, GN Separation has designed and manufactured a customized large linear vibrating screen for a client in iron ore plant. For large vibrating screens, GN Separation has three types including large linear motion vibrating screens, large banana vibrating screens and large flip-flow vibrating screens, each type has several models for a range of treating capacities.

Here is the links of GN Vibrating Screens: https://www.gnseparation.com/vibrating-screen

This GN large linear motion vibrating screen has following features:

1.GN large linear motion vibrating screen is a highly efficient choice. It is designed with single source of vibrating. The forced synchronous vibrating source can make the iron ore to jump quickly on the screen surface for a efficient treatment result.

2.For this large vibrating screen, GN uses vibrating exciter as the vibrating force provider and it is linked to the motor by means of a universal coupling. Because the universal coupling has the function as a cushion and also as a shock absorb, the vibrating force is transferred to the screening deck to the most extend.

3.Talking about the screening surface, this large vibrating screen is designed with a large vibrating surface for a separating capacity especially for this project.

4.The whole screen area is equipped with polyurethane screen panels plugged fasten on the screen deck. Comparing with steel screen meshes, the polyurethane ones have better elasticity and longer service life because of the anti-worn character.

5.The dual amplitude technology enables the the screening to be suitable for more particles,and also increases the accuracy of screening.

6.As GN has large machines for fabricating the mechanical parts, the large side walls are produced as a whole plate, without and welding in order to make the screening machine to be more durable and reliable.

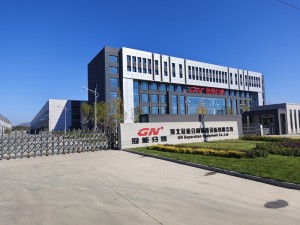

GN Separation Equipment Co. LTD

Now the machine has already started its mission at the jobsite.